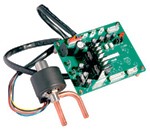

Thermostatic Expansion Valves with interchangeable orifice - RFKH series

2017/04/21

The new RFKH series of thermostatic expansion valves with interchangeable orifice developed and produced entirely by Sanhua is a natural evolution of Sanhua's existing range of RFKA thermostatic valves. This family of thermostatic valves has received enormous praise on the European market both through the distribution and spare parts industry and from machine and system manufacturers, particularly in the cooling sector. After years of creditable service, the RFKA series has been restyled in a testament to Sanhua's ongoing efforts in product optimisation: like their predecessors, RFKH series valves are configured as thermostatic valves with interchangeable orifices, a brass body, copper connections and a stainless steel head. The main noticeable difference is the use of a stainless steel bulb and capillary tube in place of copper, as used in the previous series. The increased thermal exchange obtainable with a copper bulb, which increases the valve's reactivity, has been offset by reducing the thickness of the bulb's steel cylinder. This has helped balance the steel's lower thermal exchange rate thanks to its reduced thickness, a strategy that has enabled Sanhua to maintain the valve’s excellent reactivity unchanged.

Meanwhile, the use of stainless steel in the bulb and capillary tube brings greater strength to the valve and reduces the risk of capillary tube damage in the event of accidental impacts or unusual vibrations.

RFKH series valves can be used for both cooling and air conditioning applications and are available for the main refrigerants currently on the market: R407C, R134a, R404A, R507 (a different version for R22 is available for non-EU markets).

For these traditional HFCs, a RFKH05 series has also been developed for use with R410A; this refrigerant requires a design pressure of 45 bar, which is not easily attainable with interchangeable-orifice thermostatic valves. The complex software-based design of finished elements and increased mechanical strength provided by stainless steel has enabled the company to raise the operating pressure of the RFKH valve to the required value of 45 bar. This range has also enabled manufacturers of small air-conditioning units typically operating with R410A refrigerant to see the advantages deriving from the flexibility of use of interchangeable-orifice valves. Finally, still regarding refrigerants compatible for use with the new RFKH valves, a specific series has been introduced for R407A/R407F refrigerants, proposed as a low-GWP alternative to the widespread R404A now being phased out.

The RFKH range also offers flexibility of choice in regard to types of fitting with a threaded inlet and outlet (SAE Flare), a configuration mainly used by installers, and with metric or imperial welded fittings. In the latter case, accessories such as weld adapters allow the screw fitting to be replaced with a welded fitting on the valve inlet. The valve bodies, available with internal or external equalisation, allow for the insertion of orifices with an increasing pass-through section with 8 different sizes to choose from. For example, with refrigerant R407C the capacity varies from 1.3 kW to 22.1 kW, whereas with RF410A it varies from 1.3 kW to 26.8 kW. The same orifices can be used with or without the weld adapter, which substantially reduces the number of orifice codes to be managed in the warehouse.

Sanhua Europe currently manages more than 90 RFKH codes for standard models at its European warehouse, which includes various subcategories depending on the operating temperature range. In the N (Normal) range, with temperatures between -40°C and +10°C and available with or without the MOP feature, additional series are available with different temperature ranges and dedicated to multiple applications, particularly in the field of refrigeration.

In addition to the standard models in the Sanhua Europe catalogue, products can be fully customised making them adaptable to the most demanding needs, with available models for special operating temperature ranges, MOP, or with a custom bleed (bypass) level.

In addition to the use of state-of-the-art orifices, improvements in the production process have enabled the valve to take on an even more linear behaviour, eliminating the risk of oscillations during operation.

The new range also offers improved accessories for this series of thermostatic valves, with a newly designed inlet fitting weld adapter capable of guaranteeing greater rigidity and reliability in operation, even after numerous orifice replacements.

中文

中文 English

English

Español

Español Italiano

Italiano Deutsch

Deutsch Français

Français русский

русский Português

Português 한국의

한국의