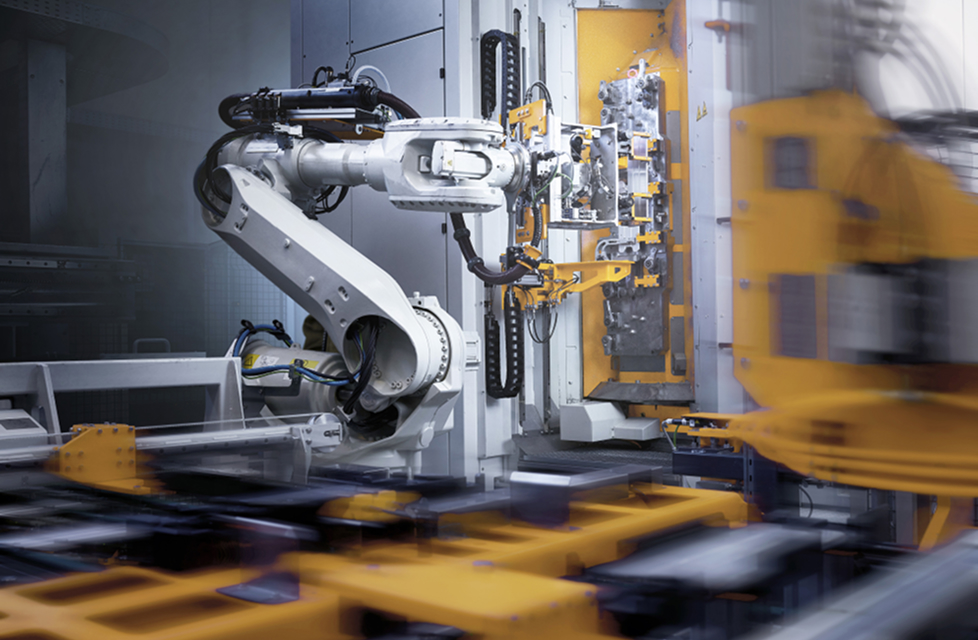

Sanhua has achieved remarkable results in "machine substitution" during production, enhancing equipment intelligence and production line automation through technologies like machine networking to improve flexibility and efficiency. Pilot digital factories have accumulated smart manufacturing experience, providing strong support for group-wide promotion of intelligent manufacturing.

Global Production Bases

Number of Industrial Robots

产线自动化率

Sanhua initially relied on manual processes with limited automation. By adopting Japanese lean production principles, it established foundational standards and management systems to enable future automation.

Sanhua embraced industrial automation via robotic arms, transmission modules, and CNC/punching machines. Core components achieved fully automated processing (loading, machining, unloading). This phase solidified Sanhua’s expertise in high-end manufacturing and quality management.

Sanhua advanced digital transformation through in-house R&D and partnerships:

Deployed MES (Manufacturing Execution System) for real-time production data analytics.

Developed PCS (Process Control System) for unified data standards and reduced equipment debugging cycles.

Built IoT-enabled digital factory models for remote monitoring and rapid troubleshooting.

In 2023, launched a "5G+Industrial Internet" platform at Shaoxing Binhai Factory, winning the First Prize in the Yangtze River Delta "5G+Industrial Internet" Competition (Equipment Track).

Sanhua is implementing its "5G-enabled Smart Factory" strategy, integrating industrial IoT and AI across facilities (e.g., Hangzhou and Binhai Plants) to achieve unmanned workshops and full lifecycle digital management.